How a Pickle Becomes a Pickle Slice

The Process

Cucumbers

All of Hausbeck’s pickles start off as cucumbers, most grown in Michigan

Fermentation Tanks

Once harvested, they are washed, sorted and graded before going into fermentation tanks filled with brine for three weeks. Hausbeck’s tank yard has 1,000 tanks, each holding approximately 50,000 pounds of cucumbers

Bubblers Remove Gases

Bubblers in the tank remove CO

2 from the brine to stop cucumbers from expanding and bloating, preventing the inside of the pickle from becoming hollow

Pickles Transported

Once ready to process, the pickles are transported to the main production facility in tubs which weigh about 2,000 pounds each

Desalting Process

At the factory, the pickles go into massive tanks kept at 70-75 degree as part of a careful desalting process

Sort & Inspect

Hausbeck employees then sort and inspect the pickles for foreign objects or blemishes as they go down the line

Custom Slicing

Next stop is the Urschel TranSlicer 2000, which cuts the pickles into customers’ desired thickness and shape

Packaging

Once cut, the pickles are weighed and mixed with customized flavored brine before they are packaged into a bag, pouch or 5 gallon container

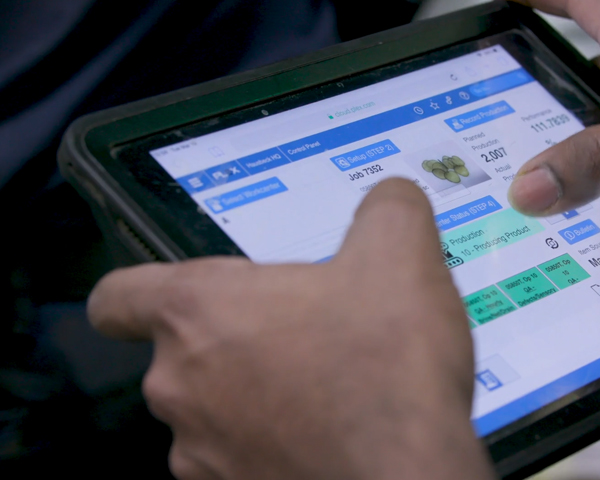

Customer Ready

A state-of-the-art information system keeps track of every batch, allowing Hausbeck to exceed industry expectations for traceability and food safety